PQ TOOL REFERENCE

1. PQ Tool Connection¶

1.1. Connect And Write Parameters¶

-

Click PQ tool

Fig 1-1 PQ tool icon

-

Disable serial port printing

For connecting the tool and serial port, please disable serial port printing and disconnect it.

Take Ikayaki series as an example: Enter 11111 in the serial port print window to stop the serial port printing information. Then disconnect.

-

Chip select

Select the chip type. Ikayaki select SsInfinity Series.

Fig 1-2 Chip type options

-

Tool config

Fig 1-3 Config and connection

First select chip series, and then click the icon to connect. If the icon is green, it is successful. If it prompts an error, please make sure that the serial port printing information is disabled and disconnected, and then try again.

-

Read register value

-

Switch to the corresponding band.

-

Enter 0x101e in the box and press Enter.

-

Click Read Bank.

-

Check the register value on the right, all zeros or all ffs indicate that the tool is not connected correctly.

-

The reference value is shown in Fig 1-5.

Fig 1-4 Read register value

Fig 1-5 Bank interface

-

-

Save the modified parameters to the board

-

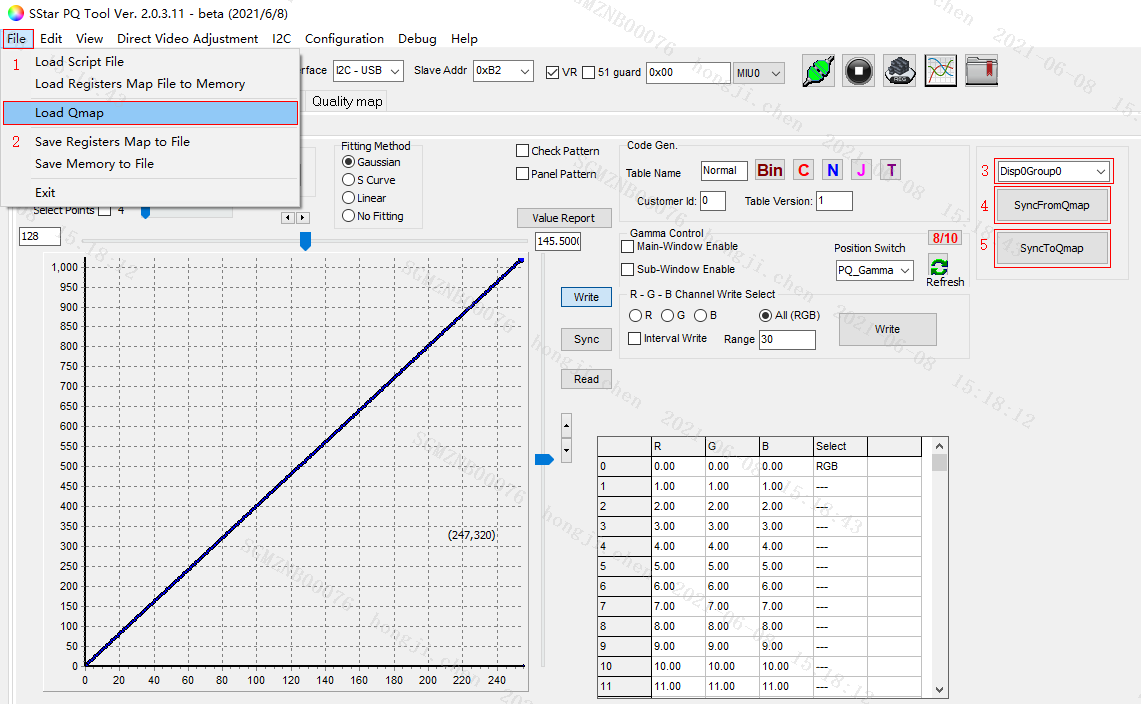

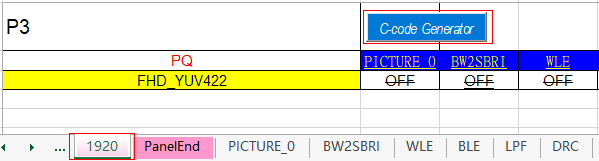

Open the QMAP table to page1920 .

-

Click

C-code generatorto generate a folder named 1920 in the root directory, as shown in Figure 1-6. -

Write

PQConfig.iniThe format is as follows:

[PQ_PATH] default = "/config/PQ.bin"

-

Pack this

iniinto the config partition, and putPQ.binin the 1920 folder in the specified path ofini, which can be changed as required, and the path ofPQConfig.inishould also be modified.

Fig 1-6 QMAP generate PQ.bin

-

2. Module Function Usage¶

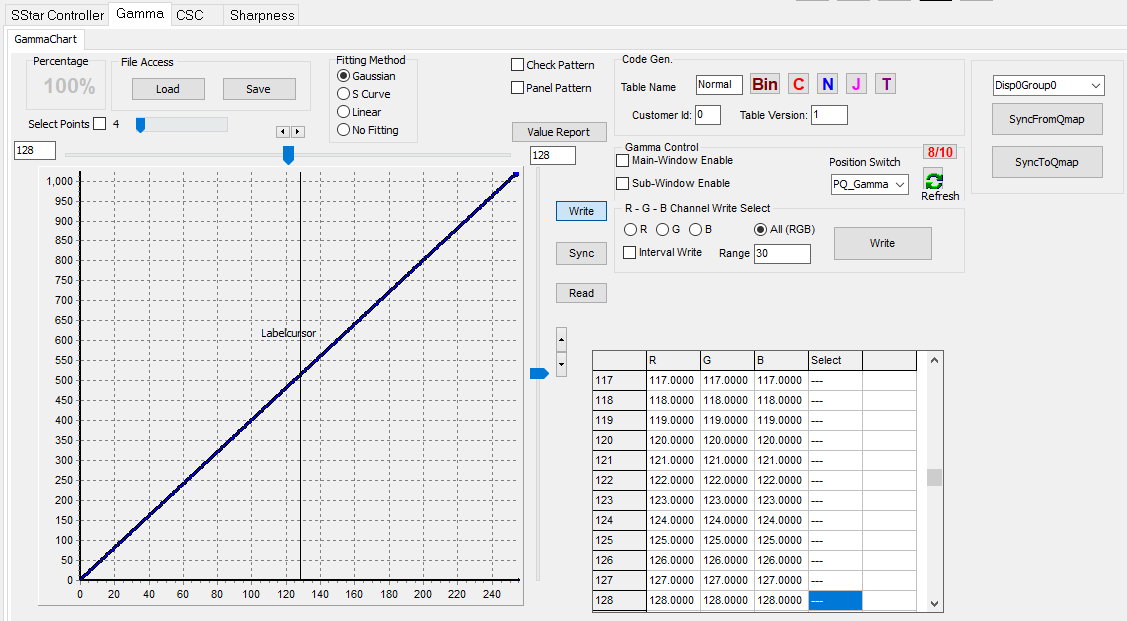

2.1. Gamma¶

-

Open the gamma subpage.

-

Select

Main-Window Enable. -

Set to adjust the R/G/B curve individually or synchronous.

-

Switch to Write, click the Write button on the right to write the debugged gamma curve to the board, which can be seen directly on the screen.

-

Switch to Read, click the Read button on the right to view the current gamma curve displayed on the tool.

-

Select Points

Automatically set the debugging node, you can also manually debug the gamma curve, and add nodes at different locations.

-

SyncFromQmap

Load the gamma parameter in the OFF column of GAMMA_0_R/G/B in Qmap.

-

SyncToQmap

Write the parameters debugged on the tool into GAMMA_0_R/G/B in the Qmap table.

Fig 2-1 Gamma debug interface

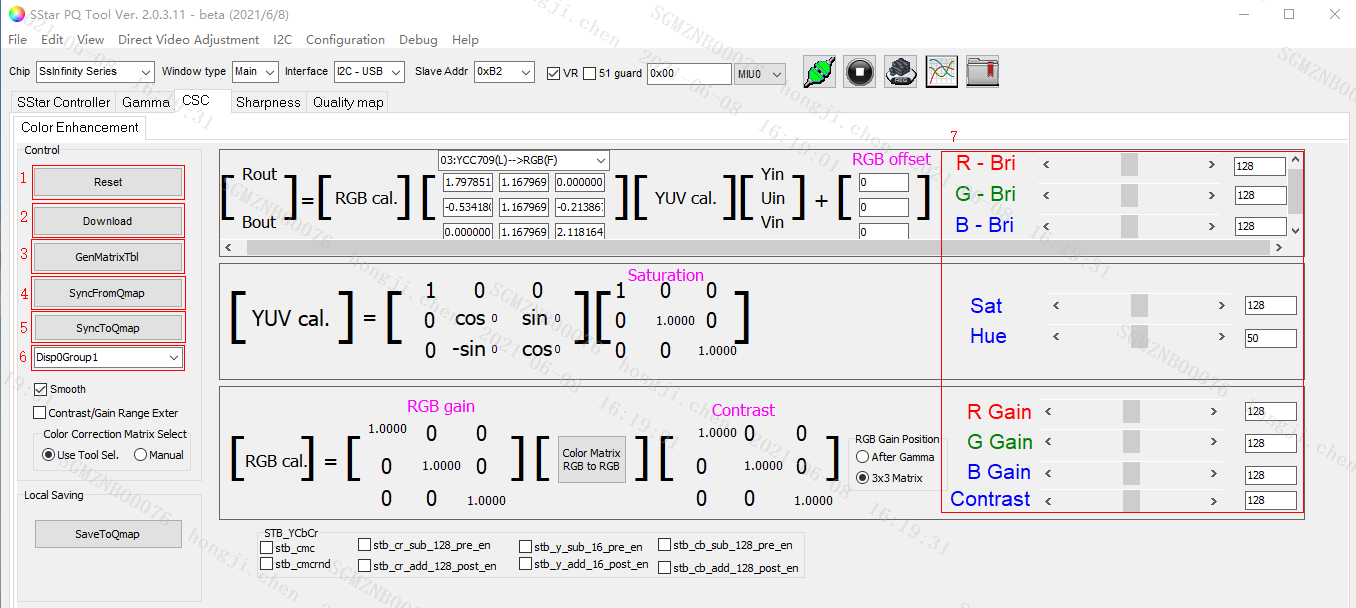

2.2. CSC¶

-

Switch to CSC.

-

Reset

Initialize the current parameters.

-

Download

Write the current debugging interface parameters to the board.

-

Restore To UI Value

Read the current value of the board and display it on the tool.

-

SyncFromQmap

Write the parameters of the current group in the QMAP table to the board.

-

SyncToQmap

Write the debugging parameters to the current group in the Qmap table.

-

Save Setting

Save the current parameter.

-

Load Setting

Import the saved parameter and display it to the tool.

-

RGB bri

RGB brightness

-

Sat

saturation, adjust the overall saturation.

-

Hue

Adjust the overall tone.

-

RGB gain

White Balance gain。

-

Contrast

Adjust the overall contrast.

Fig 2-2 CSC interface

2.3. Sharpness¶

-

2D Peaking Enable

Enable sharpness.

-

Peaking_Bank_refresh

Read and refresh the parameters of the current evaluation board and display them on the interface.

-

Save Peaking to file

Save the sharpness parameters of the current board to

Sharp_Parameter.txt. -

Save Setting

Save the current parameters to the local.

-

Load Setting

Import the locally saved parameters and display them on the tool without writing to the board.

-

SyncFromQmap

Write the data of the current group on the peaking page of the QMAP table into the board.

-

SyncToQMAP

Write the currently debugged parameters of the board into the QMAP table.

-

HVB Band B01

Adjust the sharpness intensity of B01 in the horizontal direction.

-

HVB Band B02

Adjust the sharpness intensity of B02 in the horizontal direction.

-

Coring Threshold1

Weakened the burr phenomenon after Band B01 strengthened sharpness.

-

Coring Threshold2

Weakened the burr phenomenon after Band B02 strengthened sharpness.

Fig 2-3 Sharpness

3. Note¶

The above is for the Ikayaki platform, the unspecified modules can be operated but the writing is invalid.